Wheat Grains

We at SBFPPL have aimed at adopting the most advance techniques and processes in setting of this project. In keeping with this aim we have setup the most hygienic and efficient storage facilities.

We at SBFPPL have aimed at adopting the most advance techniques and processes in setting of this project. In keeping with this aim we have setup the most hygienic and efficient storage facilities.

All grains (wheat) after pre cleaning arestored in 2 no. imported (Turkish) all weather proof silos of capacities 2200 M.T. The silos are equipped with automated computerized systems for maintaining appropriate storage environment of wheat grains.

All grains (wheat) after pre cleaning arestored in 2 no. imported (Turkish) all weather proof silos of capacities 2200 M.T. The silos are equipped with automated computerized systems for maintaining appropriate storage environment of wheat grains.

SBFPPL is the first flour mill in entire western region of India to setup this silos storage facility.

SBFPPL is the first flour mill in entire western region of India to setup this silos storage facility.

This feature will allows us scientific storage and inventory management of wheat grains throughout the year resulting in maintaining superior quality of our finished product even when supply of quality wheat grains become unstable.

This feature will allows us scientific storage and inventory management of wheat grains throughout the year resulting in maintaining superior quality of our finished product even when supply of quality wheat grains become unstable.

The current combined grain storage capacity at SBFPPL is approximately 5000 MT and plans to increase this to 8000 MT are under process.

The current combined grain storage capacity at SBFPPL is approximately 5000 MT and plans to increase this to 8000 MT are under process.

Why Us ?

SBFPPL believes in offering you only the best because you deserve it. This is reflected in the sourcing process of the Ingredients, their selection, the manufacturing process, packaging and finally the distribution of the final product. We always keeping you in mind. We leave no stone unturned in order to ensure the highest standards of food safety and hygiene. SBFPPL is engaged in ensuring implementation of world class hygiene standards across all manufacturing units. The Following are some manufacturing facilities Through Which Food manufacture at SBFPPL.

Pre and Final Cleaning Section

Pre and Final Cleaning Section

The Machinery for the main cleaning section are procured from M/s. Buhler (India) Private Limited, (A Group Company of Buhler AG of Switzerland) and pre cleaner from M/s. Fowler Westrup (India) Private Limited (A Joint Venture of John Fowler, India and Westrup, Denmark) These companies are world leader in food processing industries. The cleaning section machines comprise of Separator “Classifier”, Dry Destoner, Horizontal Scourer,Aspiration Channel, Intensive Dampener& Water Metering Device.

Wheat Grains Dampening System

Wheat Grains Dampening System

Post cleaning and before milling the grains have to be dampened and stored within the mill silos for a suitable period of time. This process is extremely important for manufacturing of quality flour. To achieve the proper dampening conditions SBFPPL has procured fully computerized and automated dampening system from FRIENDRICH electronic GmbH & Co., Germany, who are one of the world’s best manufacturer of this system. The system is so designed the it eliminates all human interaction in this process and calculates the water dosage automatically after studying various parameters such as flow rate, initial moisture, hectoliter weight and the final moisture obtained achieved of the wheat grains. This process helps to maintained homogeneity of the final product.

Grinding and Sieving section

Grinding and Sieving section

The grinding section comprising of series of roll bodies, which are the heart of any flour mill, has been fitted with Buhler make roller mill airtronic model. Buhler are the world leader in manufacturer of these machines. The sieving section comprises of double bin plansifter having aluminum screen grid assembled in aluminum frame unlike the traditional wooden plansifter. SBFPPL acquired this plansifter because of superior strength/stiffness, elimination of leakage and environmental benefits. These machines have been procured from HebeiPingle Flour Machinery Group Co. Ltd., China. The same company has also supplied the purifiers for top class purifying and grading of semolina and fine semolina.

Packing

Packing

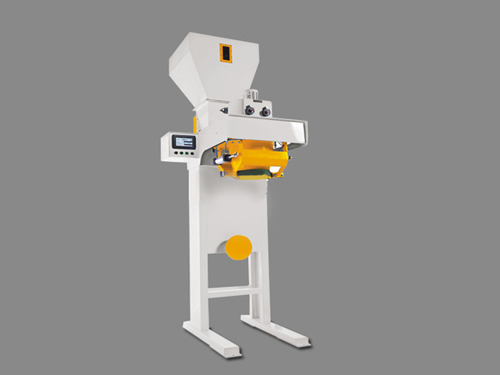

The packing section comprises of a series of quantification packing machine procured from HebeiPingle Flour Machinery Group Co. Ltd., China. These machines automatically measure and pack the flour in 5/10/25/50 kg packs.

Quality Control

Quality Control

The unit has a well-equipped laboratory for quality control purposes. It performs following important tests for grains, dough and flour.

1) Moisture determination

2) Physical analysis of Grain, insect damage, percentage of broken kernels, percentage of foreign matters

3) Determination of protein

4) Determination of gluten

5) Determination of total ash content

6) Variety of magnets totalling over 50 in nos. have been installed at various stages of cleaning, milling, packing sections to rid the processed material of any contaminants in its final product

Infrastructure

Infrastructure

A 100 metric ton capacity 18x3 meters fully computerised weighbridge comprising of imported 8 nos. Load cells and real time cameras has been installed at the entrance of the plant. The entire plant complex is covered with RCC trimix road for smooth operations of trucks. A special steel sheet barricade upto 2 feet underground and 6 feet height has been constructed at the edge of the RCC road around the mill to prevent entry of pests and rodents. M/s. Pest Control India has been given the contract for infestation control for the entire plant complex. The entire mill building and storage areas have food grade epoxy coated flooring &upto 1 feet of the wall for maintaining hygienicconditions in the plant.

Location

Location

SBFPPL has been setup at Survey No. 285, Khadoli, KhanvelSilvassa Road, Silvassa admeasuring almost 14 acres land fully enclosed by RCC/Brick boundary wall on all sides. The current project has been setup on approx 3 acres of this land. This land has been specifically chosen keeping in mind future expansion and diversification plan. This site is 18 km from NH8 and located on state highway. Silvassa is a highly industrialized township and provides ample transport and logistics solutions for pan India operations. More specifically its location and distance to major towns are a) Mumbai, Navi Mumbai and Thane District- 130 kms b) Palghar, Boiser, Dahanu, 70 km. c) Daman, Vapi, Pardi 40 Km d) Navasari, Surat 120 Km e) Nashik 130 km. The above centralized location of the plant to the major consumption centers was the key to this site selection. Furthermore, Silvassa is well connected to all wheat supplying regions viz. Gujarat, Rajasthan, Madhya Pradesh due to its proximity to NH 8 and also well connected to major shipping ports like JNPT & Hazira.